|

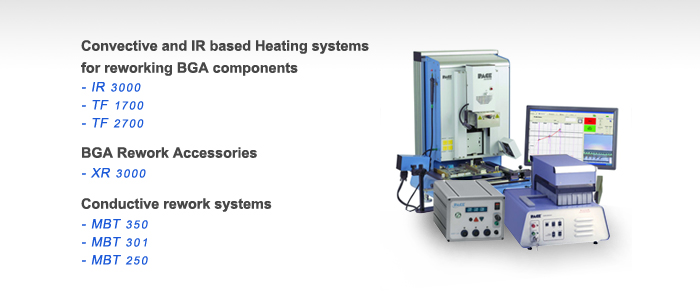

IR 3000 The IR 3000 is the newest and most advanced component rework system available on the market. The IR 3000 is fully Area Array capable and can be used to remove and install most other SMT (and thru-hole) components. |

|

TF 1700 PACE's ThermoFlo Systems (TF 1700 & TF 2700) are the next generation in automated, cost effective solutions for area array package rework. No other systems on the market have the advanced features found on these systems or is easier to use, ensuring operator acceptance and success! Designed for today's PCBs, ThermoFlo Rework Systems can safely install and remove a wide variety of CSPs, FCs, PBGAs, CBGAs, MLFs, LCCs, and other SMDs. |

|

TF 2700 PACE's ThermoFlo Systems (TF 1700 & TF 2700) are the next generation in automated, cost effective solutions for area array package rework. No other systems on the market have the advanced features found on these systems or is easier to use, ensuring operator acceptance and success! Designed for today's PCBs, ThermoFlo Rework Systems can safely install and remove a wide variety of CSPs, FCs, PBGAs, CBGAs, MLFs, LCCs, and other SMDs. |

BGA Rework Accessories

|

XR 3000 The XR 3000 is ideal for inspecting BGAs, CSPs, and other electronic components. The XR 3000 provides immediate feedback on your process using realtime images. Images can be viewed through the ThermoFlo 3000 software or through an optional, flat screen, LCD monitor when used as a standalone unit. |

CONDUCTIVE REWORK SYSTEMS

|

MBT 350 The MBT 350 from PACE is the new standard that all other rework and repair systems are measured by. The system features PACE's exclusive IntelliHeat technology and can be used with 7 different handpieces. The MBT 350 has three handpice channels that are active simultaneously. The system is fully programmable and can be password protected from unauthorized changes. The backlit, Digital, LCD screen displays the temperature of all three handpiece channels or when "scan mode" activated will cycle through the handpiece channels one at a time displaying the set and actual temperatures. The new Hi-Flo dual purpose vacuum/pressure pump and delivery system featuring PACE's patented SNAP-VAC Technology, provides the most vacuum available for desoldering applications. When used with an air pencil, the high resolution, pressure control valve allows for precise adjustment when working on the smallest components such as 0201's. |

|

MBT 301 The MBT 301 from PACE is the ideal system when solder and desolder capability are needed on the benchtop. The MBT 301 features PACE's exclusive IntelliHeat technology and can be used with 7 different handpieces. The MBT 301 has two handpice channels that are active simultaneously. The system is fully programmable and can be password protected from changes. The backlit, Digital, LCD screen displays the temperature of all three handpiece channels or with scan mode activated will cycle through the handpiece channels one at a time displaying set and actual temperatures. The new Hi-Flo dual purpose vacuum/pressure pump and delivery system featuring PACE's patented SNAP-VAC Technology, provides the most vacuum available for desoldering applications. When used with an air pencil, the high resolution, pressure control valve allows for precise adjustment when working on the smallest components such as 0201's. |

|

MBT 250 The MBT 250 has been the work horse of the rework and repair industry for well over a decade. With over 45,000 field installations, no other system has proven itself with the endurance and reliability that is experienced by MBT 250 owners. The MBT 250 is available in 3 handpiece configurations and as a stand alone system that you can purchase the handpieces you want separately. If you are interested in the next generation or upgrading to a system where PACE's patented TD-100 Thermo-Drive soldering iron included, please see the MBT 301 or MBT 350 Rework & Repair systems. |